About The Project

This project involves interfacing an ultrasonic sensor with a servo motor to measure and display distances at various angles. The system rotates the sensor across a 180-degree range, providing real-time distance readings for enhanced spatial awareness and measurement applications.

Real World Applications of the Project

- Robotics and Automation: It can be used in robotic systems to enable obstacle detection and avoidance, allowing robots to navigate safely in their environment.

- Security Systems: The system can be integrated into surveillance and security systems to monitor a wide area for intrusions or to detect objects moving within a specific range.

- Mapping and Navigation: The setup can be utilized in applications requiring environment mapping, such as in drones or autonomous vehicles, to create a 2D map of the surroundings based on distance measurements.

Ultrasonic Sensor (HC-SR04)

The working principle of an ultrasonic distance sensor is based on the echo of high-frequency sound (Ultrasonic Sound)waves.

- Sound Wave Emission: The sensor emits short pulses of ultrasonic sound waves (typically above the range of human hearing, around 40 kHz).

- Travel to Object: These sound waves travel through the air and bounce off any obstacle or object in their path.

- Echo Reception: The sensor then listens for the echoes of the sound waves reflected back from the object.

Time Calculation : By measuring the time interval between sending the sound pulse and receiving its echo, the Arduino Uno calculates the distance to the object using the formula: Distance = Speed of Sound ×Time interval between sending the sound pulse and receiving its echo/2.

Speed of Sound: The speed of sound wave in air is approximately 343 meters per second .

That is

Distance in meter = 171.5 ×Time interval between sending the sound pulse and receiving its echo in second.

Servo Motor

A servo motor is a type of motor where precise control of angular position is required.

- A servo motor receives a PWM (Pulse Width Modulation) signal on its control wire.

- The width of the pulse determines the position of the servo horn (output shaft).

- Input Signal (PWM): The control circuit receives a PWM (Pulse Width Modulation) signal, which dictates the desired position of the servo.

- Pulse Width: The length of the pulse determines the angle:

- 1 ms pulse width: Typically corresponds to 0 degrees.

- 1.5 ms pulse width: Corresponds to 90 degrees (midpoint).

- 2 ms pulse width: Corresponds to 180 degrees.

- The pulse width is sent every 20 ms in a 50 Hz (meaning the pulse is repeated every 20 ms) signal.

- Pulse Width: The length of the pulse determines the angle:

However, Arduino programming with a servo motor is straightforward, the servo motor’s position is determined by a value ranging from 0 to 180 degrees

The Servo.h library, handles the conversion of the angle value to a PWM signal with the appropriate duty cycle and frequency, controlling the servo motor’s position.

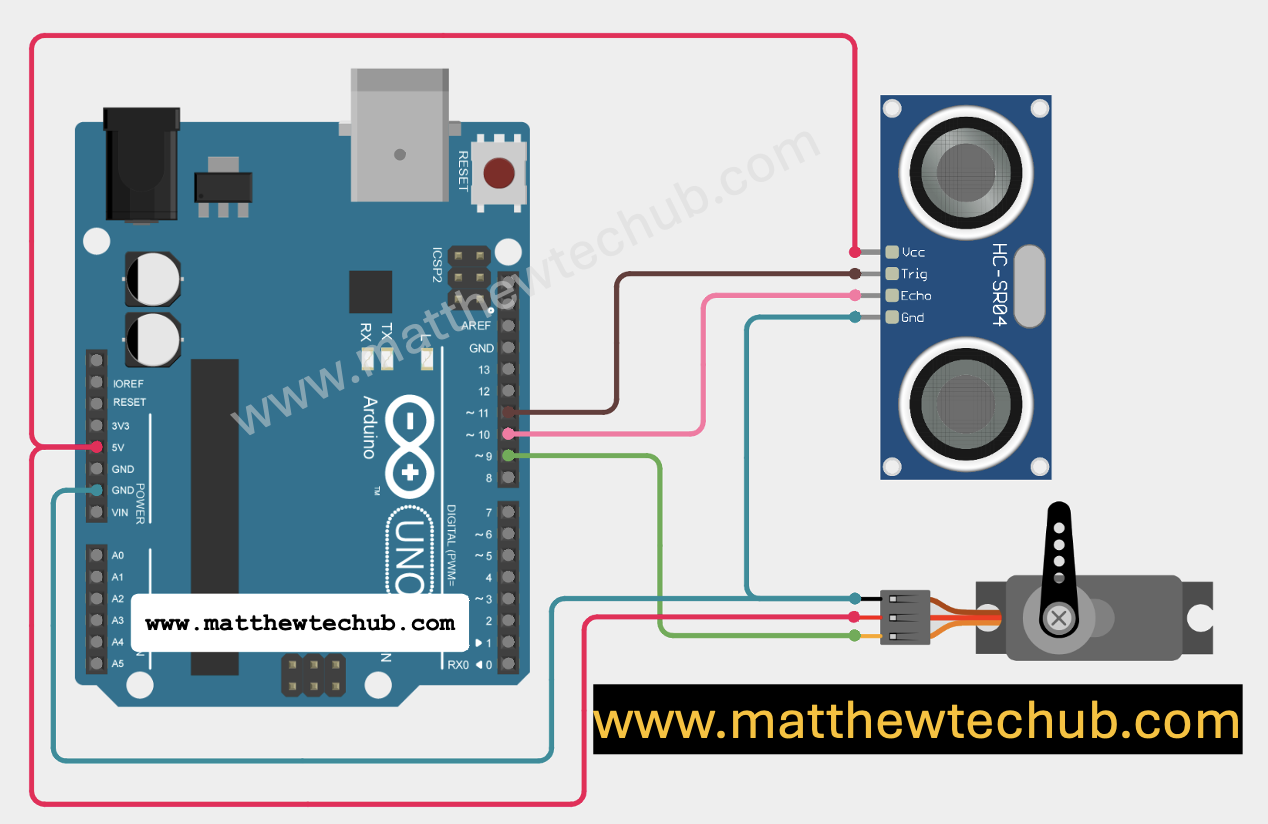

Circuit Wiring

Program Code

This Arduino code interfaces a servo motor with an ultrasonic sensor to measure the distance to objects at different angles. The setup continuously sweeps the servo motor from 0 to 180 degrees and then back to 0 degrees while measuring the distance using the ultrasonic sensor at each step. The results (angle and distance) are printed on the Serial Monitor.

// www.matthewtechub.com

// servomotor -Ultra Sonic Sensor

#include <Servo.h>

Servo myServo; // Create a servo object

// Define pins for ultrasonic sensor

const int trigPin = 11;

const int echoPin = 10;

// Variable to store distance

long duration;

int distance;

void setup() {

myServo.attach(9); // Attach the servo to pin 9

pinMode(trigPin, OUTPUT); // Set the trigPin as an output

pinMode(echoPin, INPUT); // Set the echoPin as an input

Serial.begin(9600); // Start the serial communication for debugging

// Initial test to move the servo

myServo.write(0); // Move servo to 0 degrees

delay(1000); // Wait for 1 second

myServo.write(90); // Move servo to 90 degrees

delay(1000); // Wait for 1 second

myServo.write(180);// Move servo to 180 degrees

delay(1000); // Wait for 1 second

}

void loop() {

for (int angle = 0; angle <= 180; angle += 5) { // Sweep from 0 to 180 degrees in 15-degree steps

myServo.write(angle); // Move the servo to the current angle

delay(500); // Wait for the servo to reach the position

// Send a 10us pulse to trigger the ultrasonic sensor

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

// Read the echoPin to get the duration of the pulse

duration = pulseIn(echoPin, HIGH);

// Calculate the distance in centimeters

distance = duration * 0.034 / 2;

// Print the distance and the angle

Serial.print("Angle: ");

Serial.print(angle);

Serial.print(" degrees, Distance: ");

Serial.print(distance);

Serial.println(" cm");

delay(500); // Short delay between readings

}

// Return the servo to the initial position

for (int angle = 180; angle >= 0; angle -= 5) { // Sweep back from 180 to 0 degrees

myServo.write(angle); // Move the servo to the current angle

delay(500); // Wait for the servo to reach the position

// Send a 10us pulse to trigger the ultrasonic sensor

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

// Read the echoPin to get the duration of the pulse

duration = pulseIn(echoPin, HIGH);

// Calculate the distance in centimeters

distance = duration * 0.034 / 2;

// Print the distance and the angle

Serial.print("Angle: ");

Serial.print(angle);

Serial.print(" degrees, Distance: ");

Serial.print(distance);

Serial.println(" cm");

delay(500); // Short delay between readings

}

}

Code Explanation

#include <Servo.h>- The `Servo` library is included to control the servo motor. This library simplifies the process of controlling servo motors with an Arduino.

Servo myServo;- An object `myServo` of the `Servo` class is created. This object will be used to control the servo motor.

const int trigPin = 11;

const int echoPin = 10;

- `trigPin`: The pin connected to the trigger pin of the ultrasonic sensor (used to send out a pulse).

- `echoPin`: The pin connected to the echo pin of the ultrasonic sensor (used to receive the reflected pulse).

long duration;

int distance;

- `duration`: Stores the time taken by the ultrasonic pulse to travel to the object and back.

- `distance`: Stores the calculated distance to the object in centimetres.

void setup() {

myServo.attach(9);

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

Serial.begin(9600);

}

- `myServo.attach(9)`: Attaches the servo motor to pin 9.

- `pinMode(trigPin, OUTPUT)`: Sets `trigPin` as an output, used to send out the ultrasonic pulse.

- `pinMode(echoPin, INPUT)`: Sets `echoPin` as an input, used to receive the reflected pulse.

- `Serial.begin(9600)`: Initializes serial communication at a baud rate of 9600 for debugging purposes.

- The servo motor is initially tested by moving it to 0°, 90°, and 180° positions with 1-second delays between movements.

void loop() {

for (int angle = 0; angle <= 180; angle += 5) {

myServo.write(angle);

delay(500);

- The servo motor sweeps from 0° to 180° in 5-degree increments. The `delay(500)` allows the servo time to reach each position.

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

- A 10-microsecond pulse is sent through `trigPin` to initiate the ultrasonic sensor. This pulse triggers the sensor to send out a sound wave.

duration = pulseIn(echoPin, HIGH);- The `pulseIn()` function measures the time it takes for the reflected sound wave to return to the sensor. This time is stored in `duration`.

distance = duration * 0.034 / 2;- The distance to the object is calculated based on the time taken by the pulse. The speed of sound is approximately 0.034 cm/µs, and since the pulse travels to the object and back, the time is divided by 2.

Serial.print("Angle: ");

Serial.print(angle);

Serial.print(" degrees, Distance: ");

Serial.print(distance);

Serial.println(" cm");

- The angle and corresponding distance are printed to the Serial Monitor.

for (int angle = 180; angle >= 0; angle -= 5) {

myServo.write(angle);

delay(500);

- The servo motor sweeps back from 180° to 0°, repeating the process of measuring and displaying the distance.

Summary:

- The servo motor continuously rotates from 0° to 180° and back, while the ultrasonic sensor measures the distance to objects at each angle.

- The system calculates the distance based on the time it takes for the sound wave to return after hitting an object.

- The distance and the angle are displayed on the Serial Monitor, providing real-time data on the object’s distance at various angles.

- This setup can be used for applications such as scanning an area to detect obstacles, mapping environments, or as part of a more complex robotic system.